Expertise

We have established rigorous processes that adhere to the industry’s strictest standards. Every armoured vehicle we produce undergoes thorough quality control.

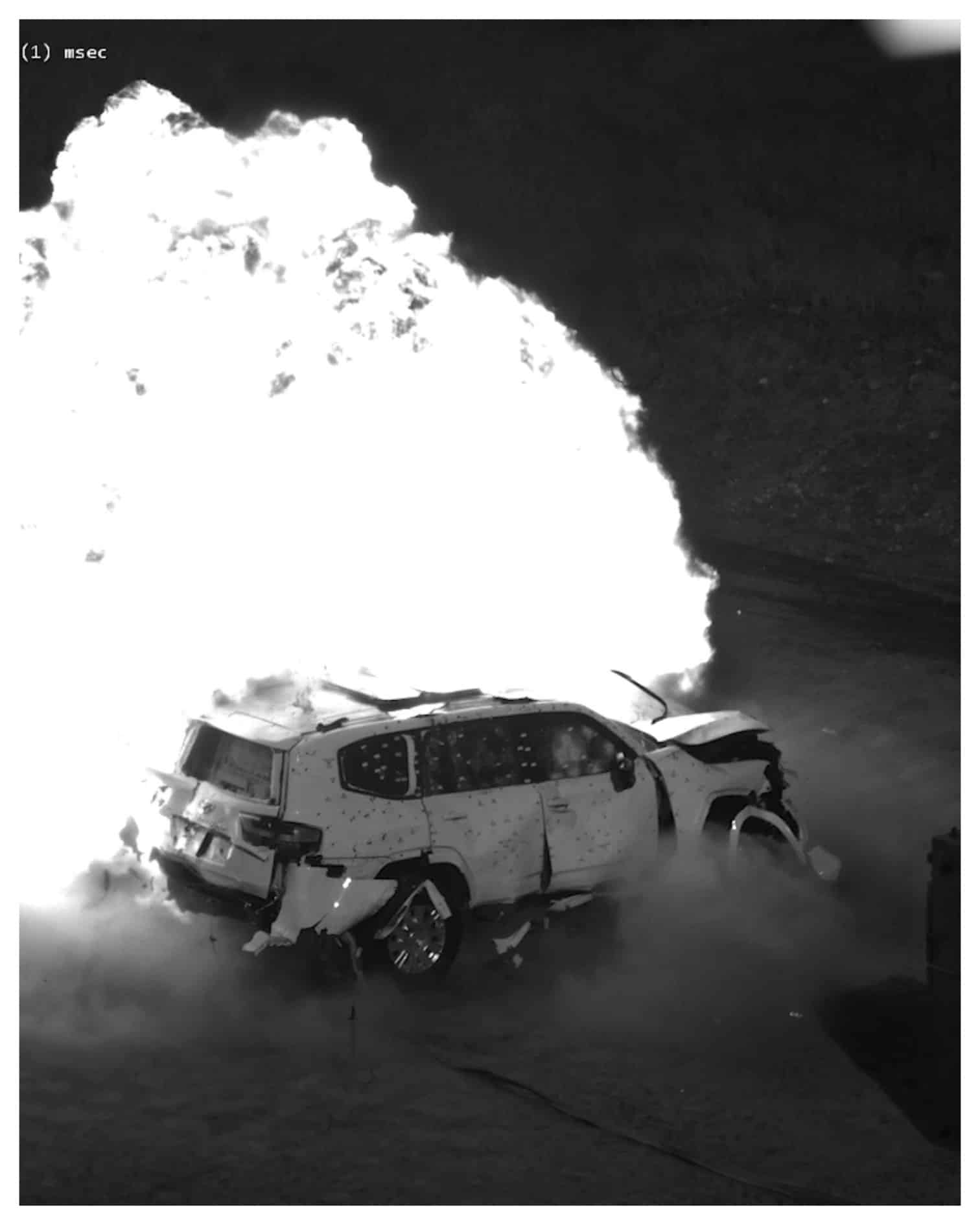

The expertise of the ballistics department

With 70 years of experience, our team of experts in protection solutions for civilian and defence markets offers deep expertise in countering aggressions.

We submit our armoured solutions to independent ballistic laboratories such as TNO, CEDREM, QinetiQ and the Beschussamt Mellrichstadt to guarantee compliance and fair comparison. To ensure the agility of our manufacturing processes, Centigon France invests in the most competitive and high-performing production equipment.

Research & Development

Our R&D team rigorously tests each ballistic protection innovation to address current and future threats. Our solutions undergo internal and external testing to ensure their effectiveness and your safety, enriching our database of armoured solutions.

Our designers and engineers work closely with our manufacturing partners to design steel, glass and composite armouring elements. Leveraging advanced software and technologies such as a Faro scanner and 3D printing, we ensure seamless integration of our protection solutions.

We take into account the integration of personalized equipment inside the armoured cab, ensuring the comfort and convenience of operators aboard our vehicles.

Our expert redesigns the essential mechanical components to maintain excellent road performance while ensuring the protection of the occupants of our armoured vehicles.

Production methods

A STATE-OF-THE-ART MANUFACTURING PLANT

Our production department covers more than 11,000 m², offering an annual capacity of almost 120,000 hours per shift (scalable as required).

Regular investments are made to meet customer expectations and enhance our facilities. Our plant boasts a welding robot, laser cutting machine, 400 T bending press, high-capacity vehicle lifts, paint booths for trucks, new drying chambers, a high-capacity shot blaster, and a “Line-X” machine.

We also prioritize our team’s health by providing effective personal protective equipment.

ARMOURING PROCESS

At Centigon France, we use two armouring methods: Cube-on and Cube-in.

With the Cube-on method, a completely new cab is engineered, built and mounted on the original chassis. The cab armour is carefully designed to mirror the original appearance or to look more imposing, depending on the operational requirements.

The Cube-in armouring process consists of integrating a steel-armoured compartment inside the vehicle, while preserving its original exterior appearance. The vehicle is completely dismantled, then the ballistic steel panels are integrated. Inside, the armouring can be plain or customized. We also apply a layer of polyurethane (Line-X) for additional protection against explosions. Our aim is to provide effective protection against ballistic and blast threats while ensuring passenger comfort.

Support Strategic After Sales Service

Centigon France’s after-sales service ensures the quality and reliability of the armoured vehicles delivered. Qualified technicians and detailed documentation guarantee operational readiness.

Services include corrective, preventive and predictive maintenance, service and maintenance contracts, vehicle overhauls, technical service in France and abroad, spare parts sales and a technical maintenance centre. We perform maintenance on armoured glass, air conditioning, servo-control systems, mechanical systems, sheet metal, paint, upholstery and chassis, wheels and braking systems.

HIGHEST STANDARDS for control and quality

Centigon France is committed to providing technical protection solutions and services that exceed customer expectations. Our quality management system ensures a fact-based approach, fostering continuous improvement and active employee engagement. Our solutions comply with stringent military standards, as well as ISO 9001 and ISO 14001.

Throughout the development process, we prioritize customer requirements, meticulously vet materials, and conduct rigorous ballistic testing. During production, we conduct thorough self-assessments at each stage, covering mechanical and electrical tests, appearance checks, seal integrity, and weight verification. We maintain detailed traceability for both components and process parameters.

Our technical protection solutions meet the highest standards for military, law enforcement and VIP missions. Our commitment to continuous improvement makes us the preferred partner for armoured solutions.